We start with a stack of 100% cotton t-shirts. These are usually picked up in batches of 5 or 10 by Jennilyn when she browses a thrift store, looking at the ones tagged on sale that day. $1 or $2 each, they accrue until we have around 30. That's what fits in our washer/dryer. You can see the stack on the counter in front of Jennilyn.

We are wearing clothes that aren't going to be ruined by bleach. This is a process that's rife with collateral bleaching...

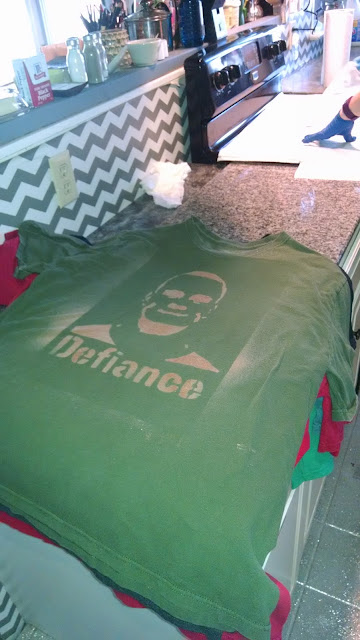

Next, Jenni lays the stencil down on a shirt and sprays a few shots of pure bleach. The stencil creates a negative resist to the spray.

On some of them, the effect is almost instantaneous. It's an interesting process to see what the "under" color is after the bleach has removed the dye.

Once the shirt has "turned" sufficiently, I quickly soak the shirt in a bowl of straight water (which turns a murky yellow due to the dye run-off) to remove any remaining liquid bleach, then rinse.

Then it gets a second soaking in a bowl of water mixed with vinegar, to stop the bleaching action. It gets wrung out again, then set aside for the washing.

There is a slow wicking of the bleach into the paper layer of the stencil. Eventually, we are going to have to replace it. Jennilyn made it from an enlarged copy of Max's freshman BYU ID. Very identifiable smirky look from Max. When the pile of shirts is thick, sometimes she has to hold the stencil flat against the shirt, which is why she's wearing rubber gloves - bleach can "burn" the skin after long exposure.

Here's an example of a shirt that was slow to turn; this is what it looks like, still wet with bleach (it only looks like shading, but it's the dampness).

Jenni tells me I really help make the process go faster. I'm just glad to be a part of it.

This is the basket almost full of shirts, ready to wash. You can see some of the other colors we had to work with in this last batch. It's more fun to see the mixture of shirts, though the most economical of batches was when we bought a 144 "remnant" shirts that were all brown. Nice to get a large number, but the variety makes the process more interesting.

Striking, how that looks like Max, and like not-Max. Backwards.

It is a sobering, tender, somber chore. I touch my son's face, over and over again, smoothing wrinkles the way I once moved hair away from his peaceful, sleeping eyes (or gently wiped food from his baby mouth).

When we speak and distribute these shirts, we've been asked how we pay for them, or whether we would ever just buy them with the graphic silk-screened on to save time. It seems to surprise people to find out we are hand-making them (I'd guess we've probably made about 500? Maybe 600?). Sometimes, people will discretely hand Jenni some cash to help with the next batch of purchases. We appreciate the support. When we spoke on APG in September, they were delighted to find out we didn't charge a speaking fee, and happy to reimburse for the purchase of our 144 shirts.

We don't mind the slow investment of a few shirts here, a dozen more there. I keep hoping to spot one "in the wild" so I can ask the wearer where they got it.

I consider making these a reverent chance to see him, to share his story.

I miss him, and am grateful to hold him again, even a little, even like this.